Our competive advantage

Individual approach

We tailor our services to every order and every client. We carefully study the details of every customer's specific requirements in order to efficiently optimize the cost of production, as well as to ensure an optimum purchase price for the customer.

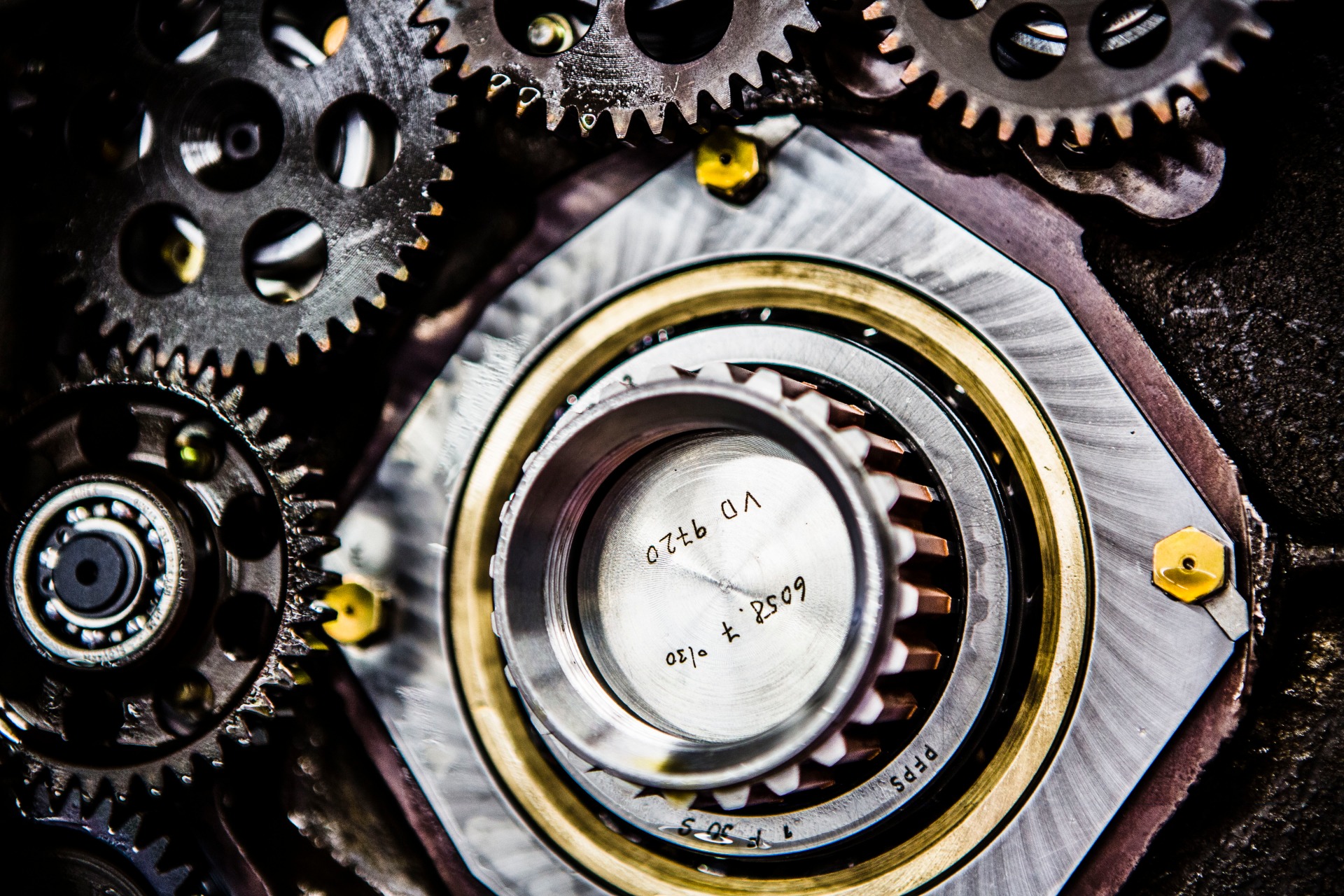

Emphasis on quality

Quality in all its aspects is crucial for us. Therefore, we regularly invest in the renewal of our technologies and purchase new equipment. We pride ourselves on the high qualification and professionalism of all our employees who belong to the best in their professions. Quality is further guaranteed by elaborate internal inspection mechanisms and implemented quality management systems.

Logistics

We have experience with logistics operations all around the world. We regularly deliver our products to the Czech Republic, but also to the USA, Canada, Argentina, France, Hungary, Romania, Germany, Austria, Poland, Turkey, India, Thailand or China.

Quality management system

The highest achievable quality of our products is very important to us and we strive to constantly improve our quality management systems. Our manufacturing operations and processes are subjected to inspections and measuring in order to assure the best possible conditions for manufacturing. Our in-house measurement lab with 3D measuring instruments and other measuring technologies are used to measure products.

Sample production

Owing to our proactive approach, we offer to manufacture samples and prototypes. In this way, our customers do not merely get to know our manufacturing possibilities, but they can also receive samples of the required products.

Completing entire projects

A number of other additional technologies enable us to complete entire projects, beginning with manufacturing (machining, pressing), carrying on with surface treatment, cleaning and packaging to finalizing projects by shipping them to our customers. Our entire production process is controlled by our comprehensive quality management system.

Regular investments

We have the latest production technology at our disposal. Our technological background is regularly innovated and we invest heavily in measuring and inspection systems, as well.

Speed and flexibility

Our ability to react to customer needs in a flexible and speedy manner is our pride. We assess every enquiry individually and try to propose the shortest possible date of production.

Specialized in mass manufactured

A larger part of our manufacturing capacities are fully automated. We also have the advantage of continuous manufacturing. This in combination with our extensive technological assets enables us to manufacture large volume orders in relatively short times.

This is our story

Since the start of 2020, CZ-AUTO SYSTEMS a.s. has been a part of the Česká zbrojovka Partners SE holding, which includes AIT Group - Advanced Industrial Technology Group a.s. Until then, CZ-AUTO was one of the production divisions of the Česká zbrojovka joint-stock company, which has more than 80 years of experience in machining and which focuses especially on manufacturing of small firearms, which are exported to more than 90 countries all over the world. On the other hand, CZ-AUTO focuses on the automotive and aviation industries and mechanical engineering. The company has already more than 45 years of experience in the aviation industry, and it ranks among the leading Czech companies with an international overreach.

Interesting facts

We are one of the leading engineering companies, a reliable supplier, offering mass manufacturing of products in above-standard quality for competitive prices. We export to a number of countries in Europe, North and South America and Asia. Here are several interesting facts about our manufacturing lines in 2019.